Intro:

Never have I claimed to be interesting. I do however, think that I have an interest in interesting things. Pre-War steel just so happens to be one of those things. Pre-War steel is an interesting material considering that it is almost identical to the steel we produce today except in one key aspect, which to our own fault, is what separates it from normal steel. In this reading, I’ll talk about what Pre-War steel is, why it’s valuable and what makes it so…cool.

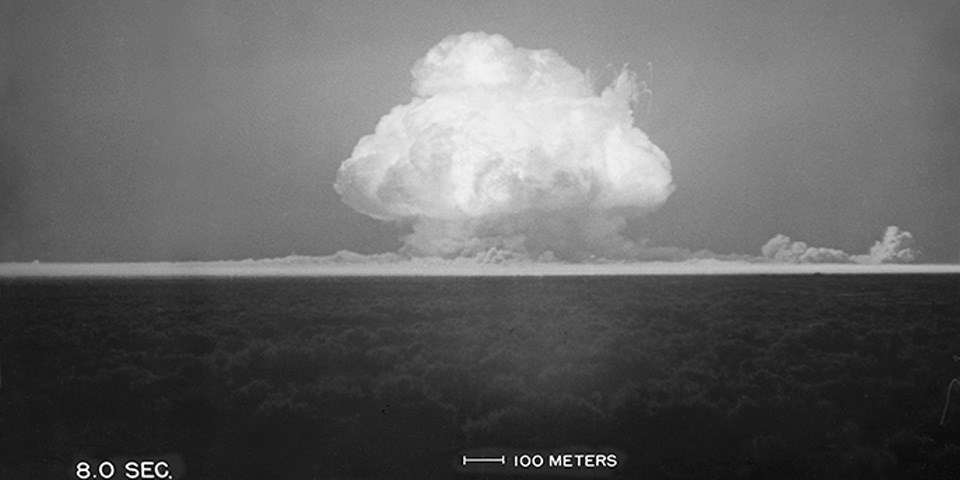

Okay! First, I’d like to talk about the history of pre-war steel, also known as "low-background steel". On July 16, 1945, The world's first nuclear explosion occurred when a plutonium implosion device (named “Gadget”) was tested at a site located 210 miles south of Los Alamos, New Mexico.

Trinity Testing Facility

In the 50 years between Gadget’s detonation and the opening for signature of the Comprehensive Nuclear-Test-Ban Treaty (CTBT) in 1996, over 2,000 nuclear device tests were executed and hundreds of those being above ground. These nuclear detonations had caused the atmosphere to be filled with radioactive particles, leading to the air we breathe becoming ever so slightly irradiated since (This is important).

It is also important to note that since the cessation of above-ground nuclear testing, background radiation has decreased significantly, to almost natural levels. But what does that have to do with steel manufacturing? Read on.

Post-War Steel:

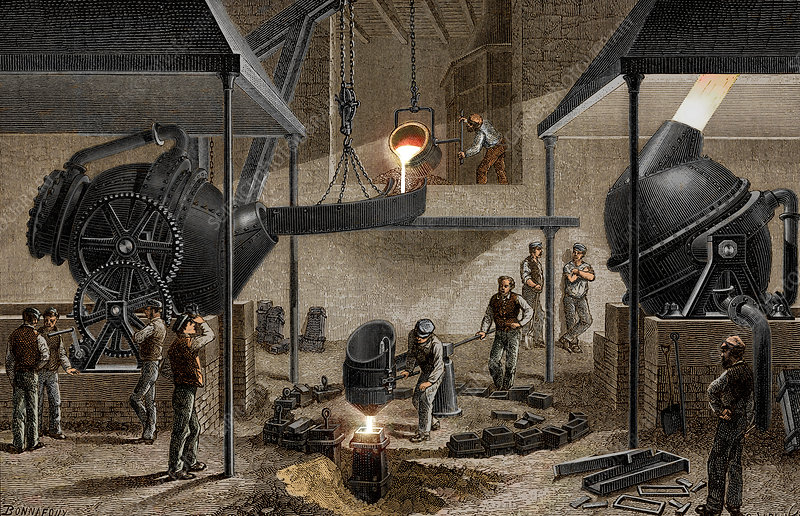

Bessemer Process Illustration

Fast forward to today, steel is still produced in a familiar fashion to it’s pre-1940’s counterpart. In a similar operation to the Bessemer process, molten iron is blasted with air to produce oxidation and in turn, removes any impurities, strengthens the alloy and maintains it’s molten state.

Here is where Pre-War steel suddenly becomes important. Remembering that since the 1940’s, the air has become contaminated with radioactive particles and this same air is used to create the steel we use today, it is safe to say that the modern steel is also now slightly irradiated.

Applications:

Knowing that the modernly produced steel is slightly radioactive, this creates conflicts in it's application. Devices and machinery that were manufactured to be radiation-sensitive could no longer effectively function and this was a problem. If your job was to sniff out radiation and you, yourself were radioactive then I suspect you'd never have a dull moment. With applications such as geiger counters, sensing equipment aboard spacecrafts and medical equipment no longer able to perform their critical duties, a solution was growing evermore needed.

Band-Aid® Solution:

Sunken WWII ship that I Googled

We have now arrived to what is, my favorite part of this history lesson. The temporary and extremely interesting solution to our need for nonradioactive steel. To recap, steel started becoming radioactive after the 1940’s when we started irradiating the air with nuclear, atmospheric explosions. So where do we find nonradioactive steel?

WE REUSE STEEL PRODUCED PRIOR TO 1940, BABY! This was commonly in the form of World War II-era shipwrecks at the bottom of the ocean. In fact, Low-Background steel was becoming so valuable that these shipwrecks were often illegally scavenged for their (now) precious metal.

The Wrap Up:

So what was the point of all this? Did we learn any sort of profound, underlying lesson about the consequences of our actions? Probably not, but Low-Background steel is still pretty awesome. The need for this material has greatly reduced as the worlds anthropogenic (nice) background radiation levels decrease. The less radioactive the air becomes, the more applications modern steel will have. I personally can't wait to see what the worlds next Pre-War steel will be.